Wrapping a pallet isn’t just about keeping boxes in one place, it’s about protecting goods, reducing transit damage and staying compliant with packaging regulations and legislations. Best Practice tells us that the goal for any warehouse or despatch operation should be in achieving load stability for pallets throughout the preparation, loading and transit phases of product delivery using the least amount of plastic as possible. So what exactly impacts wrapping pallets today?

The pallet wrapping method you choose affects not only the upfront cost but also efficiencies, as well as impacting your company’s environmental footprint too. With increasing plastic tax associated costs and growing demand for greener logistics - the question isn’t just how much does it cost to wrap a pallet, its which method delivers the best balance of cost, performance, and sustainability?

Standard stretch wrap: Cheap upfront costs per pallet, but labour intensive (when hand wrapping) and waste‑prone with poor film performance such as snapping.

High‑performance stretch wrap (machine or hand applied): More expensive per roll, but less film required on each pallet as well as being a labour efficient pallet wrap resulting in faster wrapping times.

Reusable pallet jackets and bands: A reusable pallet wrap, after the initial investment but reusable for up to 5 years. Cost per pallet wrapped dops with frequent reuse

1. Standard Stretch Wrap (Hand Film)

What it is: Thicker plastic film, typically 17 micron or more, often supplied on standard or extended cores. More film is generally required to achieve a stable pallet.

Performance: Provides basic load stability but variable results depending on operator skill and strength.

Cost drivers: Cheap roll prices, labour time (up to 4 minutes for an average pallet), film waste and injury risk to operators.

2. High‑Performance Stretch Film (Hand Film)

What it is: Engineered films with higher stretch ratios, available with recycled content to reduce plastic consumption (can be as thin as 4 or 5 micron), increase load stability as well as operator safety.

Performance: Stronger, more consistent wrapping due to the pre-stretch, does not rely on operator skill or strength to achieve optimum load stability. iWrap Hand Wrap is known for safer and more sustainable wrapping.

Cost drivers: More expensive cost per roll but faster wrapping times (under 2 minutes for an average pallet, especially when used in conjunction with dispenser such as the iWrap Hand Dispenser or even as supplied on an extended core) with benefits to the business from reduced injury risk due to safer wrapping methods and fewer damaged deliveries and re-works.

3. Standard Pallet Wrap (Machine Film)

What is it: Basic, thicker plastic wrap, can be as much as 23 micron, used on brake stretch machines which have limited stretch functionality.

Performance: Basic performance with loads susceptible to damage in transit due to lack of pallet stability. For every metre of film on the roll, when applied through the brake stretch pallet wrap machine, it results in a basic stretch of just 1.5 metres.

Cost drivers: Cheaper per roll but more needed on each pallet to try to achieve load stability. Limitations around the application of the wrap results in more damaged deliveries which all drives up expense.

4. High Performance Stretch Wrap (Machine Wrap)

What is it: High specification stretch wrap that supports best practice for warehouses looking to optimise their operations. Typically available in 10 micron or less, can contain recycled content with some high performance machine wraps containing up to 60% recycled content.

Performance: Consistent wrapping delivering reliable performance, especially when used with a Power stretch machine. This combination of pallet wrap machine and high performance wrap produces a yield of up to 3.5 metres when applied to the pallet for every metre on the roll. Brands such as iWrap Machine Wrap deliver these results consistently.

Cost drivers: Higher cost per roll but with between 250% and 300% stretch capabilities results in less wrap being required for each pallet, and hence lower costs per pallet. Savings for the business also gained through elimination of damage of goods in transit.

5. Reusable Pallet Jackets & Bands

What are they: Alternatives to plastic pallet wrap, jackets or heavy‑duty straps fitted which perform the same function as wrap in terms of securing loads, and can be removed and reused many times.

Performance: Excellent load stability, fast application times and sustainable. Best suited to a closed-loop environment. The iReuse range of pallet jackets and bands are well suited to this type of operation, helping to eliminate plastic from warehouse and despatch processes.

Cost drivers: After the original investment, these products can be used be hundreds of times with the additional saving benefits of speed of application (a matter of seconds) as well as budget saved on equipment such a pallet wrap machines and time saved on learning how to use the products.

It does not simply come down to what you pay for each roll of film, total cost of ownership (TCO) gives a fuller picture by combining material spend, labour time, equipment depreciation, compliance costs, waste disposal, and even product damage from inadequate wrapping.

By focusing on TCO rather than upfront price, businesses can make smarter, long-term decisions that balance cost efficiency with sustainability and operational performance.

Let’s examine what these number might look like:

1. List material use: metres of film, or number of reuses expected for jackets/covers.

2. Find unit price: supplier costs (film roll, jacket, band).

3. Add labour: minutes per pallet × wage rate.

4. Include equipment amortisation: machine depreciation ÷ pallets wrapped over the machine’s lifespan.

5. Factor in environmental costs: plastic packaging tax associated costs and waste disposal costs where applicable

6. Consider savings: reduced product damage, fewer rejected loads.

While this may not give you a completely accurate estimate of each product and method – it will certainly reveal some interesting insights.

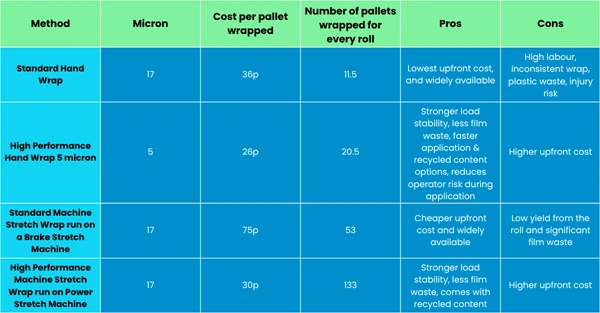

So how do the different wrapping methods stack up in terms of performance, costs and plastic needed.

The figures shown are indicative estimates only and are provided for illustration purposes to demonstrate relative costs and value drivers.

Some key learnings for you to consider for your warehouse to reduce your pallet wrap costs:

The cost of pallet wrapping depends heavily on the chosen method and products used. Standard hand pallet wrap remains cheap but labour and risk intensive. High performance hand and machine film offers efficiency gains. Reusable jackets and bands slash long‑term costs and waste. The right choice depends on your volume, supply chain, and sustainability goals.

Run the numbers with your own data you may be surprised how quickly reusables and high performance wraps pay back.