Packaging might not seem like a high-risk activity, but because it sits at the centre of manufacturing, warehousing, logistics and retail, even small issues can have a big impact on process as well as people. Workers in these environments who pack, seal, lift and palletise goods face a range of hazards, from repetitive strain injuries to trips and falls. The question for many businesses should be focussed on which packaging methods and products are associated with the lowest injury rates, and how to implement to best practice?

Discover the real physical impact of different application methods when applying pallet wrap by hand

Pallet wrapping is one of the more common packaging processes in logistics and warehousing. While it may seem straightforward, the method and products used can significantly impact worker health and safety.

The UK’s Health & Safety Executive (HSE) estimates that over 470,000 workers suffer from work related musculoskeletal disorders in the UK every year with packing and warehousing among the highest at risk. In 2023/24, musculoskeletal disorders accounted for 32% of all work-related ill-health cases and accounted for 7.8 million lost working days.

Those in Transportation and Storage roles report injuries for 1,850 cases per 100,000 workers according to Newsbywire. Common warehouse and logistics injuries include:

It’s the repetitive manual tasks that attract the most risk in warehouses but a poorly wrapped pallet irrespective of whether it’s finished by machine or hand can cause injury at any time during the despatch process. Packaging injury reduction should be an important component of warehouse safety training.

Packaging staff may wrap dozens of pallets on every shift, amplifying repetitive strain. This process increases the risk of musculoskeletal disorders (MSDs), particularly lower back injuries and shoulder strains https://www.osha.gov/data

In fact, warehouse workers are 8 times more likely to suffer from back pain and back injuries than any other industries.

Manual stretch wrapping with standard hand wrap – this process relies on operatives bending down to tie-on their pallet wrap and then proceed by walking backwards around the pallet, working up the load with consistent pressure as the wrap is applied. Workers are forced to bend, twist and walk backwards in circles to secure the loads they wrap.

Standard stretch wrap contains only basic load containment qualities. Successful stability is generally only achieved depending on the strength of the operator pulling the pallet wrap taught (increasing strain on the back, arms and shoulders) when applying the wrap and applying a considerable amount of material. Often much more plastic needs to be applied then required, or to Best Practice, compared to a pre-stretched wrap to maintain a safe load.

Manual stretch wrapping with pre-stretched hand wrap – sometimes referred to as high-performance film, wrapping with pre-stretched hand wrap such as iWrap sees an immediate improvement during the application process compared to standard pallet wrap, as it no longer relies on the strength of the operator to apply the wrap efficiently.

Pre-stretched hand wrap requires at least 50% less force during application. This means that the majority of the hard work has been done for the Operator who no longer has to apply that same level of constant tension and effort as they wrap. This helps to reduce the impact, fatigue and strain experienced compared to standard hand wrap.

Due to its consistent and reliable performance, there is far less incidence (if any) of re-wrapping and re-working due to pallet wrap failure, which again reduces the workload for the Operator.

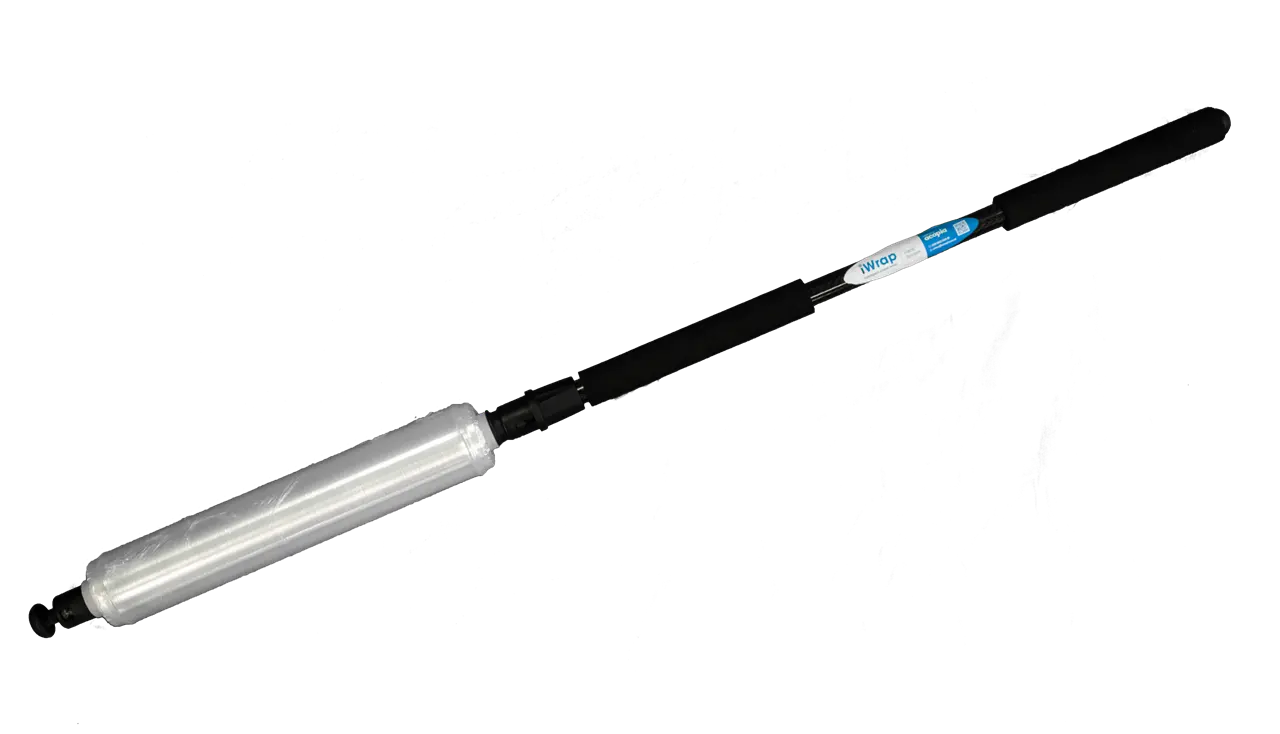

Manual stretch wrapping with dispenser – innovation is always key to unlocking improvements, and in this case, safer and more efficient working practices. The iWrap Hand System uses the powerful combination of high performance wrap (pre-stretched) and a new delivery method which reduces muscular impact by 47%. An altogether smarter and safer way to hand wrap pallets of any height, and the lightest dispenser on the market - it’s been designed ergonomically for almost effortless use

The whole system is focussed on reducing workplace injuries and improving Operator safety, as well as increasing pallet through put.

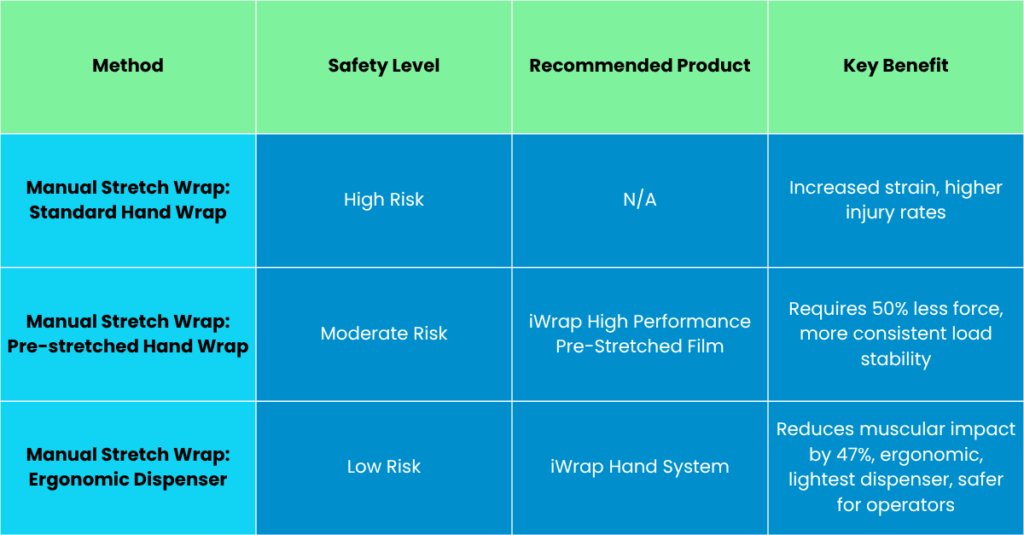

This decision tool is based on the latest best practices in pallet wrapping on reducing injuries in warehouses, logistics, and manufacturing environments. It focuses on methods and products associated with the lowest injury rates and helps guide businesses to implement safe practices.

Step 1: Assess Repetitive Strain Risk

High Risk: Manual stretch wrapping with standard hand wrap

Requires bending, twisting, walking backwards and using operator strength.

Increases musculoskeletal disorders (MSDs), particularly back and shoulder injuries.

Moderate Risk: Manual stretch wrapping with pre-stretched hand wrap (e.g., iWrap)

Requires 50% less force during application.

Reduces operator fatigue, strain and rework.

Low Risk: Manual stretch wrapping with ergonomic dispenser (e.g., iWrap Hand System)

Reduces muscular impact by up to 47%.

Ergonomic design minimises effort and repetitive strain.

Step 2: Evaluate Pallet Stability Risks

Standard hand wrap may lead to unstable pallets, requiring rewrapping and increasing operator workload and can put workers at risk from moving loads.

Pre-stretched wrap improves load containment without relying on operator strength.

Using a dispenser system ensures consistent wrap tension and reduces rework.

Step 3: Match Recommended Tools and Products to the task

If your operation is wrapping low volumes and sustainability gains is not a key driver, sticking with traditional stretch film may still be the best solution.

However, if your team are wrapping significant volumes, worker safety, reducing RSI and plastic consumption are main priorities – a pre-stretched film would most definitely be most beneficial, especially when used in combination with an ergonomic dispenser.

Step 4: Expected Safety Outcomes

By adopting pre-stretched hand wrap and ergonomic dispensers, warehouses and logistics operations can dramatically reduce injuries and improve efficiencies. Implementing these best practices aligns with the latest health and safety guidelines and protects operators from repetitive strain and workplace accidents.

If you’re interested in finding out more about how to ensure operative safety when applying pallet wrap manually, simply download the independent ergonomic study by the University of Chichester comparing different application methods that uncovers the real physical impact on operatives.