Parcel tape may seem like a small detail in the big picture of warehouse operations, but in reality, it plays a significant role in product protection, shipping efficiency, and cost management. The right tape can mean the difference between secure deliveries and costly product damage. In a packing or warehouse environment where there is increasing pressure to meet sustainability goals, every material choice matters. And with today’s buyers and customers expecting warehouses and fulfilment centres to fully embrace increased sustainability, this adds another layer of complexity to choosing the right tape.

The global demand for adhesive tape continues to grow and in 2024, over 55 million square meters were consumed across numerous industry sectors with pressure sensitive tape representing over 70% of all tapes.

Whether you’re sealing e-commerce cartons on a busy despatch bench, closing large wholesale outers on an in-line tape set up, or aiming for plastic-reduced packaging -choosing the right parcel tape is one of the fastest ways to improve despatch quality, cost, speed and recyclability.

This guide covers the main tape families, how they perform, what they cost (not just per roll), and how the right tape can help you to hit your sustainability goals without risking seal failures.

FAQ What’s pressure sensitive tape? Also known as self-adhesive tape, is a type of tape that sticks to surfaces purely with the application of pressure.

Parcel tape is used to seal and secure packages for storage and transport. It seems simple enough, but warehouses have to overcome many different packaging challenges such as preparing and shipping in varying temperatures, length of time to delivery with export consignments, long term storage, protecting tamper visibility as well as working towards more sustainable options. This means that one type of tape might not be suited to the range of requirements.

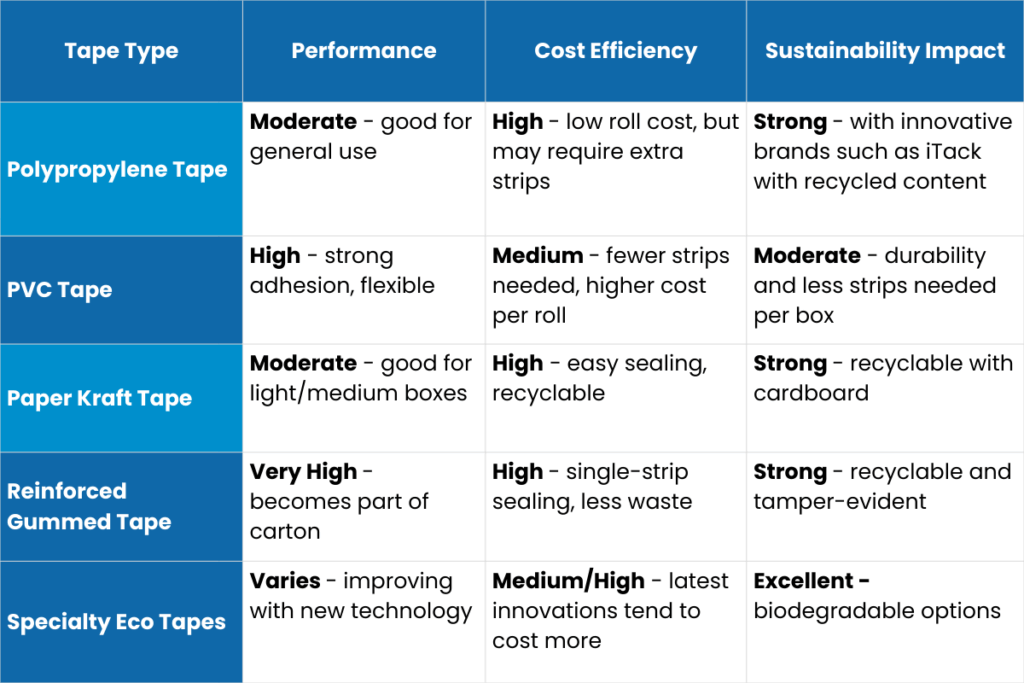

Each tape type has unique strengths and trade-offs in terms of performance, cost and sustainability.

Pro tip: An easy way to distinguish between PVC vinyl tape and polypropylene tape is by their “tearability”. Vinyl tape is easy to tear.

Performance is undoubtedly the most important factor. If the tape fails, the box fails.

Key performance factors to look at when choosing your parcel tape:

Standards and Testing bodies to consider and explore:

Performance by material:

Best Practice Tip: Train staff on correct tape application on angle, pressure and number of strips needed to create a complete seal

Performance by adhesive:

Plastic tapes

Paper-based tapes

On the surface, tape seems a minor expense. But in warehousing, the real question isn’t “What’s the cost per roll?” it’s "What's the cost per sealed box?" This is your True Cost of Ownership (TCO).

Direct Costs:

Hidden Costs:

The Pros & Cons: A “cheaper” tape that needs extra passes (or pops open) costs more in time and damages. Hot-melt’s higher price point and higher tack can mean fewer passes; WAT can reduce damages with its stronger fibre bond but requires higher initial investment

Best Practice Tip: For high-volume warehouses, a tape that seals securely with one strip instead of three can cut tape usage by more than 50% leading to significant annual time and costs savings.

Warehouses, fulfilment centres and e-commerce businesses are under increasing pressure to reduce packaging waste, even more so with the introduction of Extended Producer Responsibility (EPR)

Eco-Friendly Alternatives:

With the drive for increased environmental sustainability, this provides new opportunities for eco-friendly alternatives with 12% of new adhesive tape products launched in 2023 alone being classified as sustainable.

Environmental benefits of recycled content parcel tape

Helps to reduce the demand for new raw materials and minimises waste that would otherwise end up in landfills or contribute to pollution. By utilising recycled materials, recycled tape helps conserve natural resources, reduce energy consumption and lowers greenhouse gas emissions associated with manufacturing new products.

Smithers.com – Comparative properties recycled plastic

Ella Macarthur – Explaining the Circular Economy

Pro Tip: Many eco-friendly tapes not only reduce environmental impact but also improve brand image achieved through messaging on the tape itself regarding its eco-credentials.

Certifications and compliance to think about

One example of more sustainable pressure sensitive tapes is iTack, a collection of Plastic Packaging Tax exempt products that help organisations reach their sustainability goals faster.

iTack Polypropylene Tape is certified to contain a minimum of 30% recycled plastic content. Made from acrylic but with the instant grab and adherence properties of hot melt performance. This hybrid tape has powerful sticking power, effectively performing like a high-quality solvent-based product, yet with sustainability in every strip.

“We've strengthened our partnership with Acopia by switching to Recycled iTack®

tape for our packaging. This further supports their strong environmental values and

our sustainability goals.” Cleenol

Parcel tape is a crucial component of warehouse efficiency, product safety and brand sustainability. By considering performance, cost and sustainability together, you can make smarter decisions that reduce waste, cut costs, and support your company’s long-term growth.

The next step? Why not start by evaluating your current tape usage. Run the numbers on cost per sealed box and test some eco-friendly alternatives.

Need help with evaluating your TCO? We’re here to help, just pop us a quick email to [email protected] with any questions you may have and we can support you in choosing a tape that protects your products, your bottom line, and the planet.