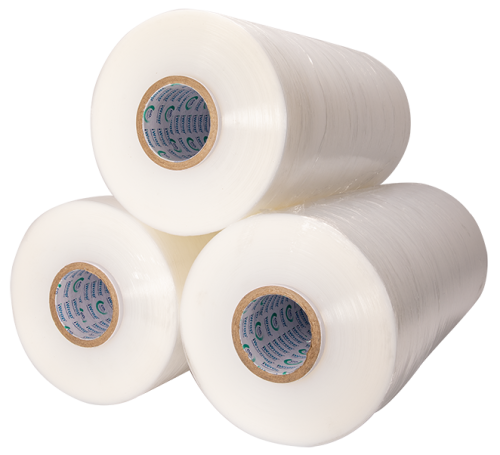

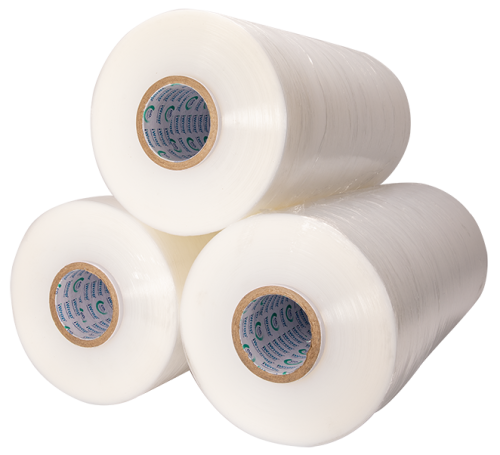

High performance stretch film

A new standard in wrapping performance

A new standard in wrapping performance

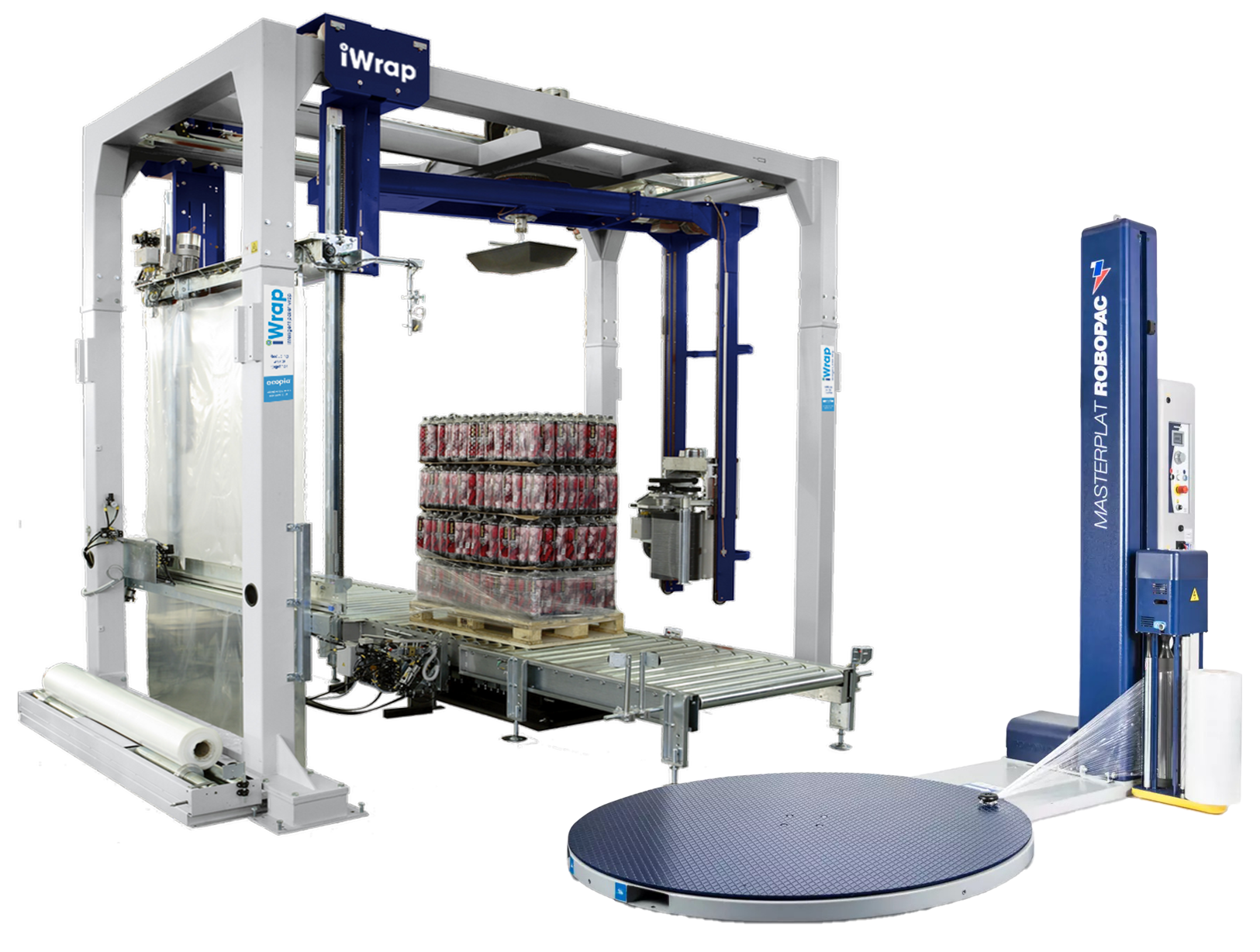

If you’re focus is moving towards carbon zero or you want to improve your environmental impact, we can support you on your journey. And it’s not just environmental savings you can expect with iWrap, the benefits will also been operationally as well as improving Health and Safety.

iWrap offers the thinnest film available without compromising on stability.

View our range of high performance machine pallet wrap below for power stretch and brake stretch applications.

Designed for use with Power Stretch Pallet Wrap Machines, the iWrap 500 series is available in five thicknesses to ensure your products have the protection and security they need during transit and storage.

These products can withstand machine rolling to stretch in excess of 300% through high-performance twin rollers, representing exceptional value. To support your sustainability agenda, iWrap 515 is available with 30% PCR.

Guaranteed pre-stretch of 300%. iWrap 510 pallet wrap is made from low density and linear low-density polyethylene (LD / LLDPE).

View productGuaranteed pre-stretch of 260%. iWrap 512 pallet wrap is made from low density and linear low-density polyethylene (LD / LLDPE).

View productGuaranteed pre-stretch of 260%. iWrap 514 pallet wrap is made from low density and linear low-density polyethylene (LD / LLDPE).

View productGuaranteed pre-stretch of 300%. iWrap 517 pallet wrap is made from low density and linear low-density polyethylene (LD / LLDPE).

View productFor less complex pallet wrapping requirements, the iWrap 400 series has been designed to work most effectively with Brake Stretch Machines where the range delivers a stretch of up to 100%.

This range is available in three thicknesses to offer a reliable level of protection in every situation.

Guaranteed pre-stretch of 180%. iWrap 408 pallet wrap is made from low density and linear low-density polyethylene (LD / LLDPE).

View productGuaranteed pre-stretch of 200%. iWrap 410 pallet wrap is made from low density and linear low-density polyethylene (LD / LLDPE).

View productGuaranteed pre-stretch of 220%. iWrap 412 pallet wrap is made from low density and linear low-density polyethylene (LD / LLDPE).

View productFor bespoke pallet formations, our Hand Wrap 300 series offers exceptional protection for even the most unusual packaging shapes. It is available in thicknesses of 5, 6 and 8mm, and in 5 or 8 micron clear film or 6 and 8 micron in blue, all with high performance low micron and each with 30% PCR.

Our high performance hand wrap is pre-stretched, so you use less plastic without sacrificing load stability. Not only that, both our Grip Film or Extended Core options come with even more sustainability and cost-cutting benefits.

Available in standard and extended core. The iWrap 305 hand wrap is made with eco-friendly 30% PLUS Recycled Content.

View productAvailable in standard and extended core. The iWrap 306 hand wrap is made with eco-friendly 30% PLUS Recycled Content.

View productAvailable in extended core. The iWrap 308 hand wrap is made with eco-friendly 30% PLUS Recycled Content.

View productAvailable in extended core. The iWrap 309 hand wrap is made with eco-friendly 30% PLUS Recycled Content.

View productLoad stability is critical when it comes to safer working in the warehouse. Not just for staff palletising but it’s important for everyone who is involved in the whole despatch and delivery process who can all potentially be at risk.

Using iWrap means pallet wrap failure is a thing of the past. The science behind iWrap high performance film means this it is incredibly thin yet incredibly strong. iWrap is pre-stretched which means when a load is subjected to external pressure, movement is contained so there is no loss of stability, resulting in a safe working and despatch environment.

Using iWrap speeds up the whole process of palletising, whether you’re wrapping by hand or machine.

There are time and operational improvements such as improved production line stoppages, reduced manual handling due to requiring less rolls of film, as well as being able to use much less plastic when despatching goods resulting in a reduced carbon footprint.

The customers we work with typically see cost improvements of around 30% on their pallet wrap spend – but the savings don’t just stop there.

One of our customers saw an increase of operational efficiency which meant they won back 26 working days just on roll changes alone.